Finding the right cordless drill can be overwhelming, especially with so many options on the market. If you’re like many buyers, you’re probably concerned with getting the best combination of power, battery life, and usability. After all, a cordless drill is an investment, and choosing the right one impacts not only the ease of your projects but also your bottom line.

To select the best cordless drill, consider factors like power rating, battery efficiency, torque, and overall durability. A good cordless drill isn’t just about drilling holes; it’s about maximizing efficiency, saving time, and ensuring quality.

So, where do you start? Understanding the specifications and how they relate to your needs is the key. We’re here to guide you through the process.

What Power Rating Should You Look For?

The power rating of a cordless drill, usually measured in volts, plays a crucial role in determining its performance. For most tasks, a range of 12V to 20V is suitable. Lighter applications, like assembling furniture or basic repairs, typically require 12-14V for ease and efficiency. For more demanding jobs, such as drilling through tougher materials, 18-20V provides the additional power needed.

Recent surveys show that over 60% of users prefer 18V drills due to their balanced combination of power and portability (source). It’s important to note, though, that higher voltages can impact battery life. Choosing the right power rating involves balancing your need for power with considerations for battery longevity.

What Type of Battery Should You Choose?

Choosing the right battery type is essential for getting the most out of your cordless drill. Lithium-ion batteries are now the industry standard because they offer high energy density, a longer lifespan, and no memory effect, which was a common issue with older Ni-Cd batteries. Lithium-ion batteries provide consistent power throughout their charge cycle, making them highly reliable for both light and heavy-duty tasks.

Battery capacity, measured in amp-hours (Ah), is also important. A higher Ah rating indicates a longer runtime, which is crucial for intensive users. For example, a 4.0Ah battery or higher is ideal for extended, demanding tasks. Studies indicate that drills equipped with higher Ah batteries can perform up to 25% longer under rigorous use conditions [source].

Here’s a comparison table to help you choose the best battery type and capacity for your needs:

| Battery Type | Key Features | Best For | Pros | Cons |

|---|---|---|---|---|

| Lithium-Ion (Li-ion) | High energy density, no memory effect | Most applications | Long lifespan, consistent power | Higher cost |

| Nickel-Cadmium (Ni-Cd) | Lower energy density, has memory effect | Occasional light-duty use | Lower cost | Shorter lifespan, heavy weight |

| Battery Capacity (Ah) | Estimated Runtime | Suitable For | Pros | Cons |

|---|---|---|---|---|

| 1.5Ah | Short runtime | Light-duty, quick tasks | Lightweight, affordable | Limited use time |

| 2.0Ah – 3.0Ah | Moderate runtime | General-purpose tasks | Good balance of weight and runtime | May need recharging frequently |

| 4.0Ah and above | Extended runtime | Heavy-duty, prolonged tasks | Longer use time, fewer recharges | Heavier, more expensive |

With this table, you can make a more informed decision based on your specific needs, ensuring you get a battery that delivers the right balance of power, runtime, and cost-effectiveness.

Choosing the right battery type and capacity is essential for maximizing performance and efficiency. Whether you’re a casual user or a heavy-duty professional, selecting the right battery ensures you have the power you need when you need it.

How Much Torque is Enough?

Torque is the force that allows a drill to drive screws and penetrate tough materials effectively. Drills with adjustable torque settings provide greater control, letting you tailor the force to match the specific demands of each task. For heavier-duty applications, a drill with higher torque is essential. Many professionals recommend a minimum of 300 in-lbs of torque for a drill that can handle a wide range of tasks efficiently [source].

When working with softer materials, using a lower torque setting helps prevent damage, while harder materials require higher torque to avoid stalling. Finding the right balance of torque not only enhances precision but can also save time and reduce project costs.

Does RPM Matter?

Yes, RPM (revolutions per minute) is a crucial factor in a drill’s performance. Higher RPM means faster drilling, which is particularly useful for tasks like drilling into wood or metal. For maximum versatility, look for drills with adjustable speed settings, typically ranging from 0-500 RPM for low-speed tasks to 0-2000 RPM for high-speed drilling.

Drills with dual-speed settings offer greater flexibility, allowing you to switch between low speeds for driving screws and high speeds for drilling. Most mid-level cordless drills come with these two-speed options, making them well-suited for a variety of tasks and materials.

What is the Importance of Chuck Size?

Chuck size is essential because it determines the maximum diameter of drill bits that the drill can hold. The two most common chuck sizes are 3/8” and 1/2”. For larger projects or tasks that require thicker, more robust bits, a 1/2” chuck is typically the better choice, offering greater versatility for handling demanding jobs across various materials.

On the other hand, if your work involves lighter-duty tasks, a 3/8” chuck is often more suitable. It’s lighter and easier to maneuver, providing better control for precision tasks. Selecting the right chuck size ensures that your drill can handle the specific requirements of your projects, balancing power with control and ease of use.

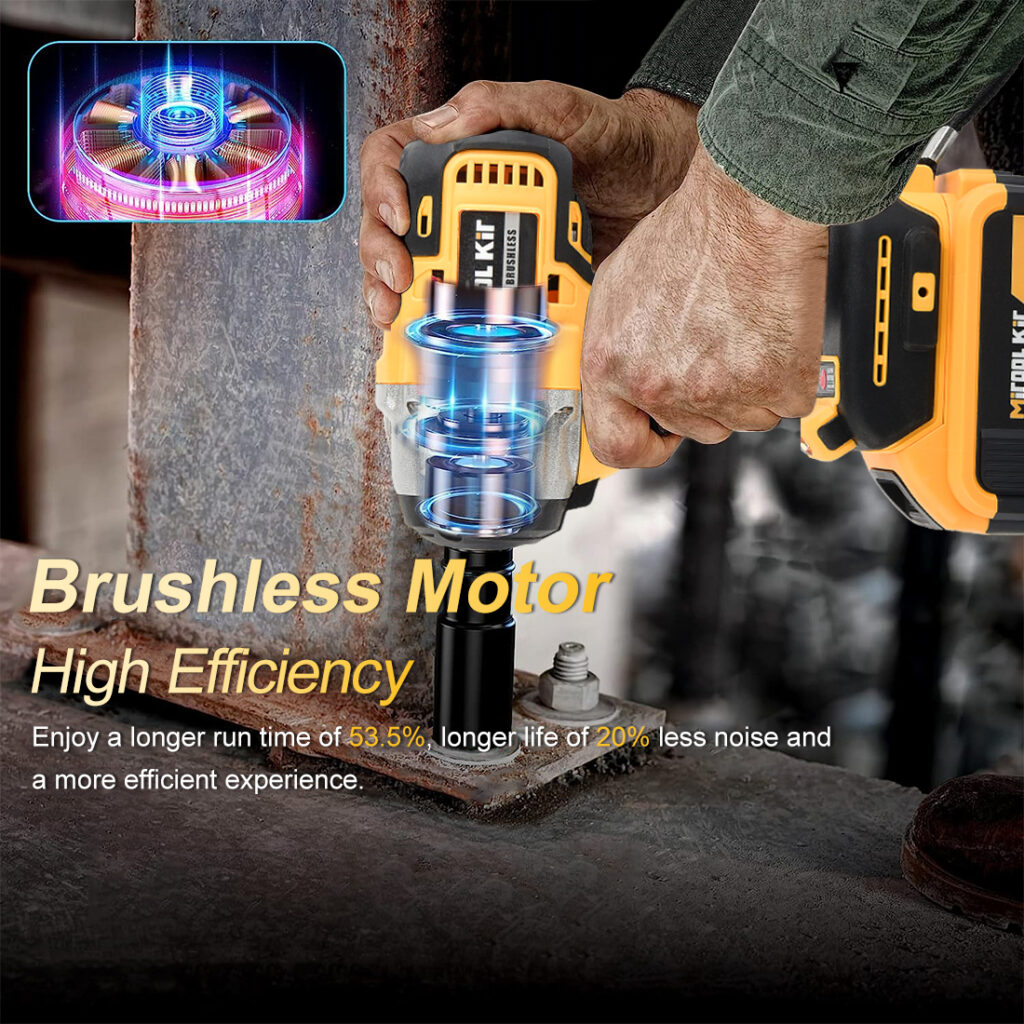

Should You Consider Brushless Motors?

Brushless motors represent a significant advancement in power tool technology, designed to improve efficiency and durability. These motors generate less heat, use energy more effectively, and can extend the tool’s lifespan. The benefit? Up to 50% longer run times per charge and less need for maintenance.

For heavy-duty tasks or professional applications, opting for a drill with a brushless motor can provide substantial time and cost savings over the long term. It’s an ideal choice for those who need reliable, high-performance tools for demanding work.

What About the Weight and Ergonomics?

The weight and design of a cordless drill are important factors to consider, as they can greatly affect ease of use. A lighter drill is easier to handle, especially for tasks in tight spaces or overhead positions. Additionally, prioritizing ergonomics is essential—choose a drill with a comfortable grip that reduces hand and wrist strain.

Drills weighing between 2.5 to 4 pounds generally provide a good balance of power and comfort. An ergonomic design not only minimizes fatigue but also helps improve overall productivity, making long tasks easier to manage.

Key Takeaways

Selecting the right cordless drill isn’t just about buying the most powerful model; it’s about matching the tool to your needs. Here’s a quick recap of the main factors:

- Power Rating (Voltage): Choose according to your task’s intensity.

- Battery Type & Capacity: Go for lithium-ion, preferably with a higher Ah rating.

- Torque & RPM: Adjustable settings provide versatility.

- Chuck Size: 1/2″ offers more flexibility, 3/8″ is for lighter work.

- Motor Type: Brushless motors add efficiency.

- Weight & Ergonomics: Choose what feels comfortable for prolonged use.

Each of these aspects contributes to the effectiveness and comfort of your cordless drill, helping you complete tasks with confidence.

Conclusion

Choosing the right cordless drill boils down to knowing what you need for the tasks at hand. By understanding the specifications, you can make a well-informed decision that ensures value for your investment. Whether for home or professional use, there’s a cordless drill out there that’s a perfect fit.