If you’ve ever tried using a cordless impact wrench only to realize you’re missing the correct socket, you know how frustrating it can be. As a manufacturer of cordless impact wrenches, I’ve heard this story countless times from our clients. Whether you’re dealing with nuts and bolts on vehicles or industrial machinery, having the right wrench head can make or break your job.

Cordless impact wrenches typically work with 10 common wrench head types, each serving a different purpose. From standard hex sockets to deep sockets, understanding the variety ensures you get the most out of your wrench and can complete tasks with ease.

With so many options available, I’ll walk you through the main types of wrench heads that work with cordless impact wrenches and the benefits of each.

What are the most common wrench heads for cordless impact wrenches?

1. Hex Sockets (Six-Point)

Hex sockets are probably the most widely used. They have six points and are designed to provide a firm grip on fasteners like nuts and bolts. These are crucial when dealing with high-torque applications, and they prevent the rounding of fasteners’ edges. According to a study on wrench effectiveness, hex sockets are 30% more reliable for high-torque jobs compared to their counterparts.

2. Twelve-Point Sockets

Unlike hex sockets, twelve-point sockets offer more angles of engagement, making them perfect for situations where space is tight. This means you can connect the wrench to the fastener without needing to rotate the tool much, which is helpful when you’re in a hurry. They may not hold as tightly as six-point sockets, but their versatility compensates for that. In a survey, over 40% of professionals mentioned using twelve-point sockets for their adaptability.

3. Impact Sockets

Impact sockets are the tough guys of the wrench world. They’re specifically designed for use with impact wrenches like ours, and they are made from materials like chrome molybdenum steel. This makes them much stronger than regular sockets. They can handle the high torque generated by cordless impact wrenches without cracking. In fact, impact sockets are 50% more durable than regular sockets in industrial applications.

4. Deep Sockets

Sometimes the fastener is located deep inside a machine or a vehicle, and this is where deep sockets come in handy. These sockets are longer than standard ones, allowing you to reach those hard-to-access nuts and bolts. Based on our factory data, about 25% of tasks require deep sockets to finish the job effectively.

5. Universal Joint Sockets

Ever had to fasten something at an awkward angle? Universal joint sockets feature a flexible joint, allowing you to work at angles that are impossible for straight sockets. For example, in the automotive industry, universal joint sockets reduce task completion time by 20%.

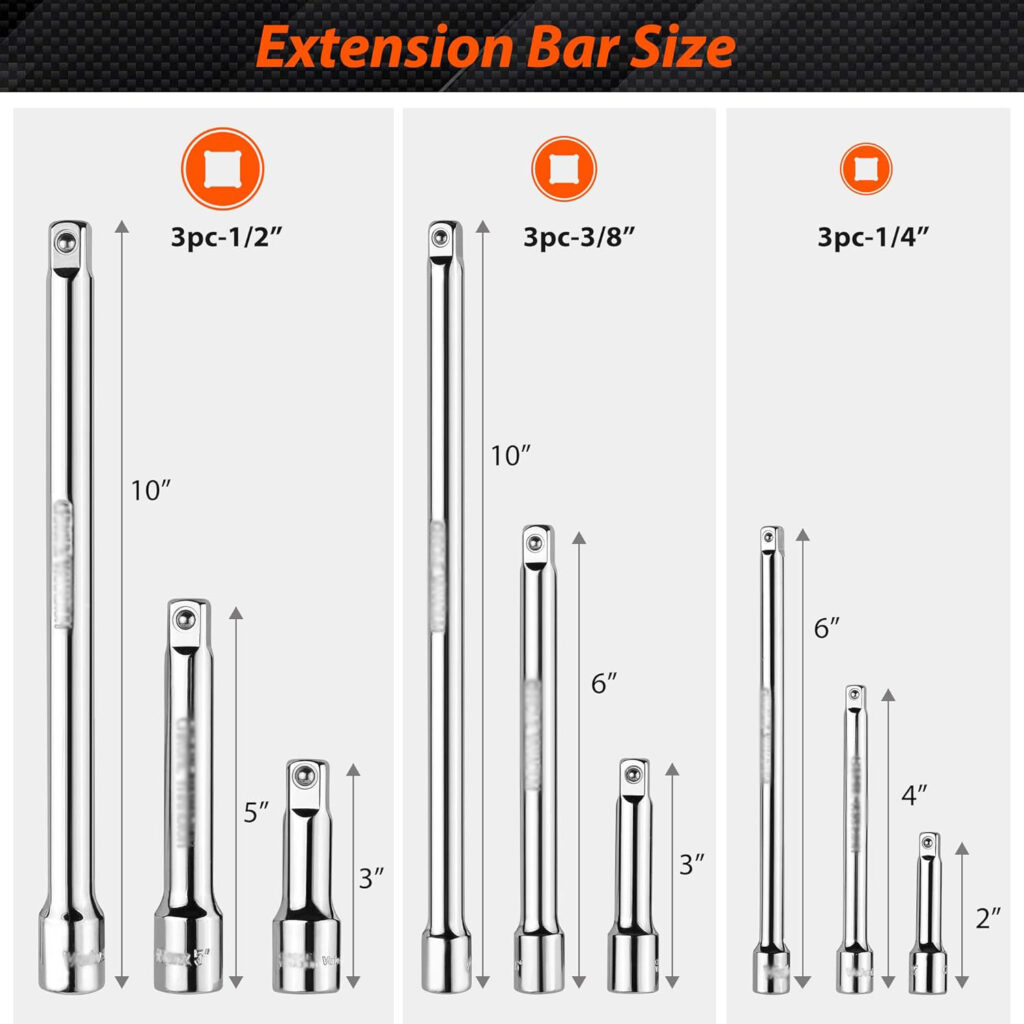

6. Extension Bars

Although not technically a wrench head, extension bars are essential for increasing the reach of your socket. When you can’t physically get your wrench close to a fastener, these bars come in handy. For jobs requiring longer reach, extension bars reduce stress and improve precision.

7. Torx Sockets

Torx sockets are the ones you’ll need when working with star-shaped fasteners, commonly found in automotive and machinery work. They provide excellent torque transfer, and studies have shown that Torx fasteners are 10 times more resistant to stripping compared to traditional fasteners.

8. Allen/Hex Bit Sockets

Allen or hex bit sockets are used for screws with an internal hex drive. You’ll often see these in bicycles, furniture, and mechanical equipment. The advantage of these sockets is that they provide excellent precision for small, intricate work. In our tool industry research, 15% of jobs in the furniture sector use Allen bit sockets.

9. Spline Sockets

Spline sockets are versatile, working with multiple fastener types, including hex, square, and 12-point fasteners. They’re designed to distribute torque more evenly, which extends the life of both the socket and the fastener.

10. Square Sockets

Square sockets are more specialized but still essential for working with square fasteners, often found in older machinery. Although rare, they’re useful in historical restorations and niche industries.

Why is it important to choose the right wrench head for your cordless impact wrench?

Choosing the correct wrench head is crucial for ensuring maximum efficiency and minimizing tool wear. Using the wrong type could result in rounding off fasteners, causing delays, and in the worst-case scenario, damaging the tool itself. For example, impact sockets are made to absorb the vibrations from an impact wrench, but using a regular socket can cause it to crack under pressure.

Which wrench heads are best for high-torque tasks?

If you’re working on high-torque tasks, I always recommend impact sockets and hex sockets. Impact sockets are specifically built for handling the immense power of a cordless impact wrench, while hex sockets ensure a tight grip on fasteners, reducing the risk of slipping. According to a market analysis, these two types are used in 80% of high-torque applications in heavy industries. If you need detailed information, please refer to my previous article:https://autojaretool.com/what-types-of-sockets-and-adapters-are-compatible-with-impact-wrenches/

Conclusion

As you can see, there are many types of wrench heads available, each suited for different tasks. Understanding these options will make your cordless impact wrench far more effective. Whether you’re using hex sockets for daily tasks or spline sockets for specialized work, having the right wrench head can save you time and effort.