Impact wrenches are indispensable tools in industries like automotive repair, construction, and manufacturing. Their ability to deliver high torque output with minimal effort makes them essential for loosening or tightening bolts and nuts, even in challenging environments. Among the key innovations that have significantly enhanced the performance of modern impact wrenches is the introduction of brushless motors. These motors have revolutionized the industry by offering superior efficiency, reliability, and longevity. This article explores the advantages of brushless motors in impact wrenches, detailing how they improve performance and why they are favored over traditional brushed motors

1. Enhanced Efficiency and Power Output

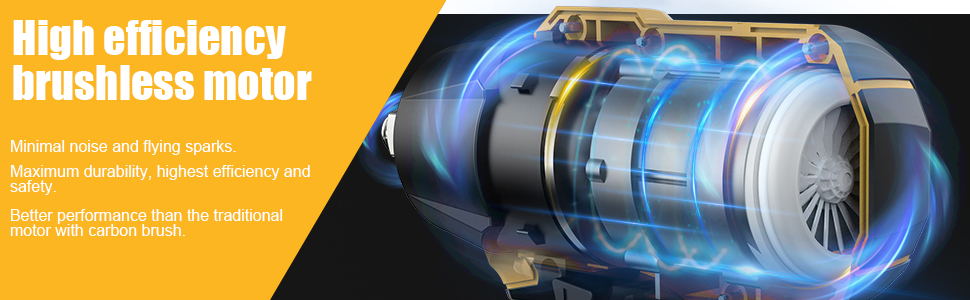

One of the most significant advantages of brushless motors in impact wrenches is their superior efficiency. In a brushless motor, the absence of physical brushes results in less friction, allowing more electrical energy to be converted into mechanical energy. This improvement in energy conversion directly translates into better power output and performance.

For impact wrenches, which require bursts of high torque to operate effectively, a brushless motor can consistently deliver that power without significant energy loss. This efficiency allows brushless motors to perform at a higher level than brushed motors, especially under demanding conditions where continuous power is essential.

2. Longer Tool Lifespan

Brushless motors have fewer moving parts compared to brushed motors. In traditional brushed motors, carbon brushes are in constant contact with the rotor, generating friction and wear over time. This friction leads to the gradual degradation of the brushes, requiring regular maintenance and eventual replacement.

In contrast, brushless motors eliminate the need for brushes altogether, as they use electronic commutation to manage the motor’s operation. By reducing the number of wear-prone components, brushless motors significantly extend the lifespan of impact wrenches. The absence of physical contact also means that there is less heat generation, further reducing the risk of overheating and premature failure of the motor components.

For professionals using impact wrenches daily in industrial settings, the extended lifespan of a brushless motor translates to reduced downtime, lower maintenance costs, and greater overall tool reliability.

3. Better Heat Management

Impact wrenches are often used in high-torque applications, generating significant amounts of heat during prolonged use. Excessive heat can lead to reduced performance, tool failure, or even safety risks if not properly managed. Brushless motors are more effective at dissipating heat because they generate less internal friction compared to brushed motors. This reduction in heat allows the motor to operate at lower temperatures, even during extended periods of heavy-duty use.

In a brushless motor, the use of electronic sensors and control systems also allows for better monitoring and regulation of motor temperature. Some impact wrenches with brushless motors are equipped with built-in thermal protection, automatically adjusting the motor’s performance to prevent overheating. This feature helps extend the motor’s lifespan and ensures that the tool can continue to operate efficiently in demanding conditions.

Here’s a table representing the key points from the paragraph:

| Aspect | Description |

|---|---|

| High-Torque Applications | Impact wrenches are used in high-torque applications, generating significant heat during prolonged use. |

| Heat Concerns | Excessive heat can reduce performance, cause tool failure, or lead to safety risks if not managed properly. |

| Brushless Motors Advantage | Brushless motors dissipate heat more effectively due to less internal friction compared to brushed motors, operating at lower temperatures during extended heavy use. |

| Electronic Sensors and Control | Brushless motors use electronic sensors and control systems for better temperature monitoring and regulation. |

| Thermal Protection | Some brushless impact wrenches have built-in thermal protection, automatically adjusting motor performance to prevent overheating. |

| Extended Lifespan and Efficiency | The thermal protection feature helps extend the motor’s lifespan and ensures efficient operation in demanding conditions. |

4. Increased Durability and Resistance to Harsh Environments

Impact wrenches are frequently used in harsh environments, such as construction sites, automotive repair shops, and outdoor settings, where they are exposed to dust, debris, moisture, and extreme temperatures. Traditional brushed motors are more vulnerable to these environmental factors because the exposed brushes can accumulate dust and dirt, leading to clogging and reduced performance.

Brushless motors, on the other hand, are sealed and better protected against environmental contaminants. The lack of exposed brushes makes them more resistant to dust and dirt, ensuring that the motor remains clean and functional for longer periods. This durability makes brushless impact wrenches ideal for use in rugged environments, where reliability and resilience are critical.

Moreover, the electronic control systems in brushless motors can further enhance their durability by providing features like overload protection, preventing damage to the motor when it is subjected to extreme conditions or heavy loads.

5. Higher Torque-to-Weight Ratio

In any portable power tool, the balance between power and weight is crucial for user comfort and efficiency. Brushless motors offer a higher torque-to-weight ratio compared to brushed motors. This means that for a given size and weight, a brushless motor can produce more torque than its brushed counterpart.

For impact wrenches, this advantage is particularly important. A higher torque-to-weight ratio allows manufacturers to design lighter, more compact tools without compromising on performance. This improved balance makes brushless impact wrenches easier to handle, reducing user fatigue during extended use. It also enhances maneuverability, allowing operators to work in tight spaces or overhead without being burdened by the tool’s weight.

6. Greater Control and Precision

Brushless motors are equipped with advanced electronic control systems that allow for greater precision and control in impact wrench operation. These systems can monitor and adjust the motor’s performance in real-time, providing more consistent torque delivery and smoother operation.

Many brushless impact wrenches feature multiple speed and torque settings, allowing users to tailor the tool’s performance to specific tasks. This level of control is particularly beneficial in applications that require a delicate touch, such as assembling sensitive components or working with soft materials that could be damaged by excessive force.

The electronic controls also enable features such as automatic shutoff or variable speed triggers, which improve user control and reduce the risk of over-tightening or damaging fasteners. This precision makes brushless impact wrenches ideal for both high-torque applications and more intricate tasks where accuracy is essential.

7. Lower Maintenance Requirements

As previously mentioned, brushed motors require regular maintenance due to the wear and tear of the carbon brushes. These brushes need to be inspected and replaced periodically, especially in high-use tools like impact wrenches. This maintenance can lead to tool downtime, which is costly in professional settings where productivity is paramount.

Brushless motors, with their fewer moving parts and lack of brushes, significantly reduce the need for maintenance. There are no brushes to replace, and the overall design is more robust, requiring less frequent inspections and upkeep. This reduction in maintenance saves time and money for users, particularly in industrial environments where tools are subjected to heavy use.

The long-term cost savings associated with brushless motors are substantial. While brushless impact wrenches may have a higher upfront cost compared to brushed models, the lower maintenance requirements and longer lifespan result in a more cost-effective investment over time.

8. Improved Battery Efficiency

In cordless impact wrenches, battery life is a critical factor. Brushless motors are more energy-efficient than brushed motors, meaning they can provide the same or even higher levels of performance while consuming less power. This efficiency translates to longer battery life, allowing users to complete more tasks on a single charge.

For professionals working in environments where access to power outlets is limited, such as construction sites or outdoor settings, the extended battery life of brushless impact wrenches is a significant advantage. Longer runtime reduces the need for frequent battery changes or recharges, increasing productivity and minimizing interruptions.

Additionally, the improved efficiency of brushless motors means that they can generate more torque without draining the battery as quickly. This allows cordless brushless impact wrenches to compete with corded models in terms of power, making them a versatile option for both light and heavy-duty applications.

9. Quieter Operation

While noise reduction may not be the primary concern for all users, it is worth noting that brushless motors tend to operate more quietly than brushed motors. The absence of friction between brushes and the commutator in brushless motors reduces noise during operation.

In industrial or construction settings, where multiple power tools may be in use simultaneously, quieter operation can contribute to a more comfortable working environment. It also reduces the strain on workers’ hearing, which is particularly beneficial in settings where hearing protection is not always used.

Conclusion

The advantages of brushless motors in impact wrenches are numerous and significant. From enhanced efficiency and power output to longer tool lifespan and better heat management, brushless motors offer a range of benefits that make them the preferred choice for professionals and serious DIY enthusiasts alike. The reduced maintenance requirements, improved battery efficiency, and increased durability further solidify brushless impact wrenches as a superior option over their brushed counterparts.

While brushless impact wrenches may come with a higher initial cost, the long-term benefits of improved performance, reliability, and cost savings make them a worthwhile investment for anyone seeking a high-quality, durable, and efficient tool. Whether you’re working in automotive repair, construction, or any other industry that demands reliable torque and power, a brushless impact wrench is a tool that will enhance your efficiency and precision.