Cordless impact wrenches have gained popularity among professionals and DIY enthusiasts alike, thanks to their convenience and flexibility. Without the hassle of power cords, they allow for easier maneuverability and usage in tight spaces. However, users sometimes find that their cordless impact wrench doesn’t deliver the torque or power they need for specific tasks. This article will explore common reasons for this issue and provide practical solutions to help you get the most out of your tool.This issue can arise from various factors, ranging from battery performance to the tool’s mechanical condition, all of which affect the overall efficiency of the wrench. This article delves into the possible reasons for weak power output from your cordless impact wrench and provides actionable solutions to help you maximize its performance.

Common Reasons for Weak Cordless Impact Wrench Power

Before addressing the lack of power, it’s crucial to understand the common causes of this issue. By identifying these factors, you can take targeted actions to resolve the problem.

1. Low Battery Charge

One of the most common reasons for a weak cordless impact wrench is a low battery charge. Since cordless tools rely on battery power, insufficient charge can drastically reduce the tool’s torque and power output. This is something many users overlook, especially after prolonged use without recharging, resulting in a noticeable drop in performance.

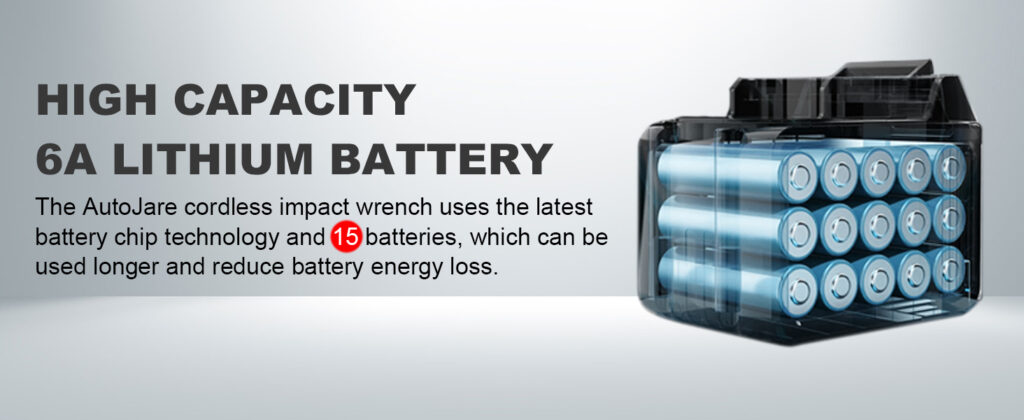

2. Battery Capacity Limitations

Even with a fully charged battery, the capacity of the battery can affect the tool’s power output. Different batteries (e.g., 2.0Ah, 4.0Ah, 5.0Ah) provide varying levels of performance, and a smaller battery may not be able to sustain high torque output for extended periods.

3. Incorrect Gear Setting

Many high-performance cordless impact wrenches come with multiple gear settings, allowing users to switch between low-speed, high-torque settings, and high-speed, low-torque settings. If the wrong gear setting is used for a specific task, it can result in insufficient power output. For example, using a lower gear for a high-torque task will naturally result in weaker performance.

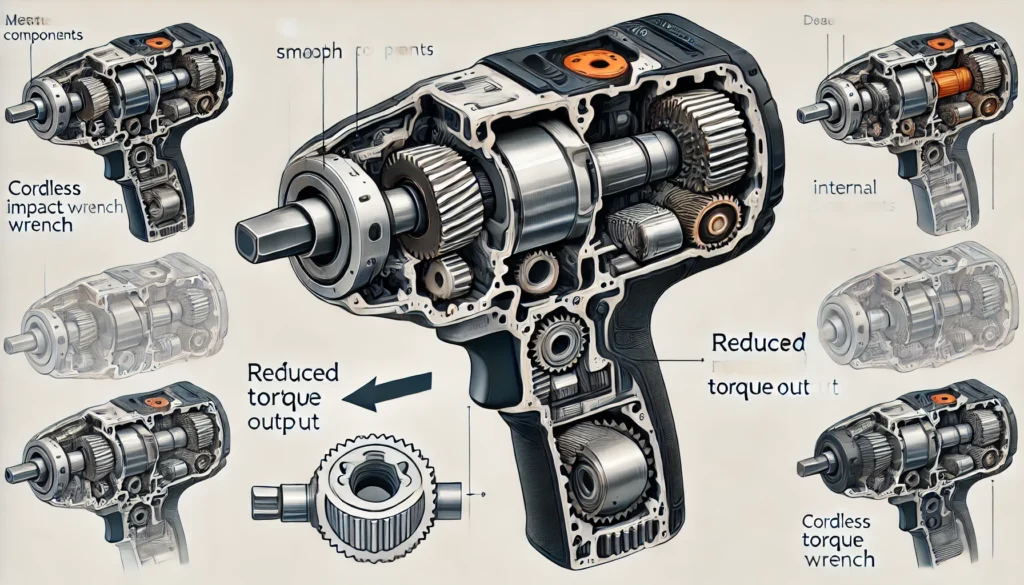

4. Mechanical Wear and Tear

Over time, the internal components of a cordless impact wrench, especially gears and bearings, may wear out due to prolonged use or high workloads. This can reduce the overall performance and lead to a noticeable drop in torque output compared to when the tool was new.

5. Inappropriate Working Environment

Extreme temperatures, especially cold, can affect the performance of cordless impact wrenches. Cold weather can reduce battery efficiency, leading to weaker performance. Dusty or damp conditions can also impact the tool’s motor and other components, further diminishing its power.

Solutions to Weak Cordless Impact Wrench Power

Now that we’ve discussed the possible causes, let’s explore several effective solutions that can help you restore or even improve the performance of your cordless impact wrench.

1. Ensure Sufficient Battery Charge

The simplest solution is to make sure that the battery is fully charged before use. Most cordless tools come equipped with a battery indicator light, so if the battery is low, recharge it promptly. This is especially important when preparing for high-demand tasks. A low battery will significantly reduce the torque output, leading to diminished performance.

It’s also a good idea to develop a habit of regularly charging your batteries, ensuring they don’t run down completely or sit idle for long periods without charging, which could shorten their lifespan.

2. Use a Higher-Capacity Battery

If you are using a low-capacity battery, such as a 2.0Ah or 3.0Ah model, and find that your tool lacks power, upgrading to a higher-capacity battery can make a significant difference. A 4.0Ah or 5.0Ah battery will provide a longer-lasting power supply, ensuring more consistent torque output, even during heavy-duty applications.

Many professionals opt for larger-capacity batteries, especially when working on tasks that require continuous high torque. The larger batteries not only provide more power but also tend to deliver it more consistently over time, resulting in a more reliable performance.

3. Select the Right Gear Setting

Most cordless impact wrenches feature multiple gear settings designed to accommodate different tasks. Lower gear settings are suitable for precision tasks like fastening small bolts, while higher gear settings are designed for tasks requiring high torque, such as loosening tight bolts.

If you find that your tool feels weak, try switching to a higher gear setting to unlock more power and torque output.

4. Perform Regular Tool Maintenance

Just like any other piece of machinery, a cordless impact wrench requires regular maintenance to stay in top condition. Without proper upkeep, the tool may wear down, resulting in decreased performance over time. Here are a few maintenance tips to keep your wrench operating at full power:

- Lubricate Moving Parts: Gears, bearings, and other moving components inside the tool can wear out if not properly lubricated. Regularly applying a suitable lubricant can reduce friction and extend the life of these components.

- Clean Out Dust and Debris: Over time, dust and debris can accumulate inside the tool, especially if used in dusty environments. This can clog ventilation and affect motor efficiency. Use compressed air to blow out dust and keep the internals clean.

- Inspect for Wear and Tear: Check the tool for signs of wear and tear, such as worn-out gears, broken parts, or loose connections. Replacing worn components promptly can prevent further damage and restore the tool’s power.

5. Optimize Your Working Environment

Certain environmental conditions, such as extreme cold or high humidity, can negatively affect both battery life and tool performance. Cold temperatures reduce battery efficiency, which in turn affects the tool’s power output. If you often work in cold environments, consider keeping spare batteries in a warmer place and switching them out when needed.

Similarly, if you are working in dusty or damp conditions, make sure to regularly clean and maintain the tool. Dust and moisture can build up inside the tool, causing damage to the motor and reducing power output.

6. Consider Upgrading the Tool

If all other measures fail and the tool still feels weak, it may be time to upgrade to a more powerful model. Many high-end cordless impact wrenches now offer increased torque output and feature smart technology that adjusts power based on the task at hand. These tools are designed to handle more demanding applications and offer longer battery life, making them a better choice for heavy-duty work.

When choosing a new tool, consider factors like torque output, battery compatibility, and tool weight. For example, models with torque ratings above 1,000N·m are ideal for heavy-duty applications, such as removing rusted bolts or working with tough materials. At the same time, ensuring that the tool is compatible with your existing battery system can save you money and make the transition smoother. More details ,you can browse our article : https://autojaretool.com/how-do-i-choose-the-right-size-and-type-of-impact-wrench/

Conclusion

Although a weak cordless impact wrench can negatively affect your work efficiency, the issue can often be resolved with simple battery management, gear adjustment, and regular tool maintenance. If, after trying these adjustments, the problem persists, upgrading to a more powerful tool or using a higher-capacity battery may be the best solution. Choosing the right tool and maintaining it properly will not only improve work efficiency but also extend the lifespan of your cordless impact wrench, leading to a better overall work experience.