Screws are widely used as fasteners in life and production. However, in the process of use, there will be problems that the screw cannot be removed due to various reasons such as rust, thread deformation, and breakage. How to solve this problem? Let’s take a look at the methods that make it easy to remove the screws..

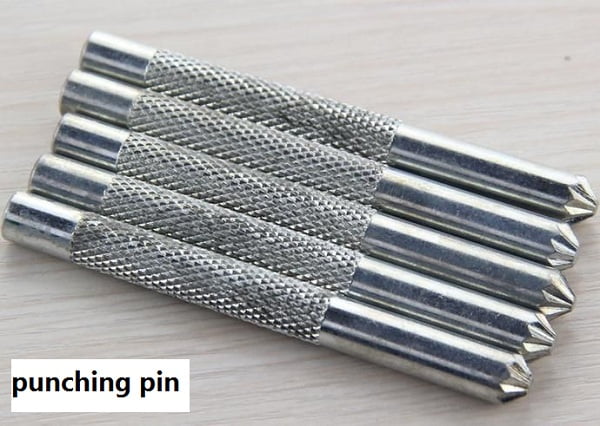

First, remove the sludge from the broken screw section, crack the center of the section with tweezers and then install a 6-8mm diameter drill bit with a drill, drill the hole at the center of the section, and pay attention to the hole. Passing.

Once the hole has been drilled, remove the tiny drill bit and replace it with a 16 mm diameter drill bit, continuously enlarging the hole for the broken bolt and drilling through.

Take a welding rod with a diameter of 3.2mm or less, pass a small to medium current in the broken bolt hole, and weld the seam from the inside out.

The part where the weld is started can take off half of the entire length of the bolt. When starting surfacing, the arc should not be too long to avoid burning the outer wall of the broken bolt. After surfacing to the upper-end face of the broken bolt, a cylinder of 14-16 mm in diameter and 8-10 mm in height is continuously welded.

3.After the electro-impact hammer weld is formed, the end face is struck with a hammer, causing the broken bolt to vibrate along its axial direction. The heat generated by the electric arc and the subsequent cooling, combined with the vibration at this point, causes loosening between the broken bolt and the body threads.

Carefully observe that when a trace of rust is found to leak from the fracture after tapping, the nut sleeve of M18 can be taken on the stud of the surfacing, and the two are welded together.

After welding, use a plum wrench cover for the excellent hot heat, twist the left and right on the nut, or twist the side of the nut with a small hand hammer while twisting back and forth so that the broken bolt can be taken out.

After removing the broken bolt, use a suitable wire hammer to machine the frames and remove any rust and other debris from the hole.

Whether it is the tiny screws of electronic equipment, the available screws of furniture appliances, or even the large screws used in engineering, construction, bridges, transportation equipment, airplanes, trams, automobiles, etc., screws occupy a critical position in these fields.